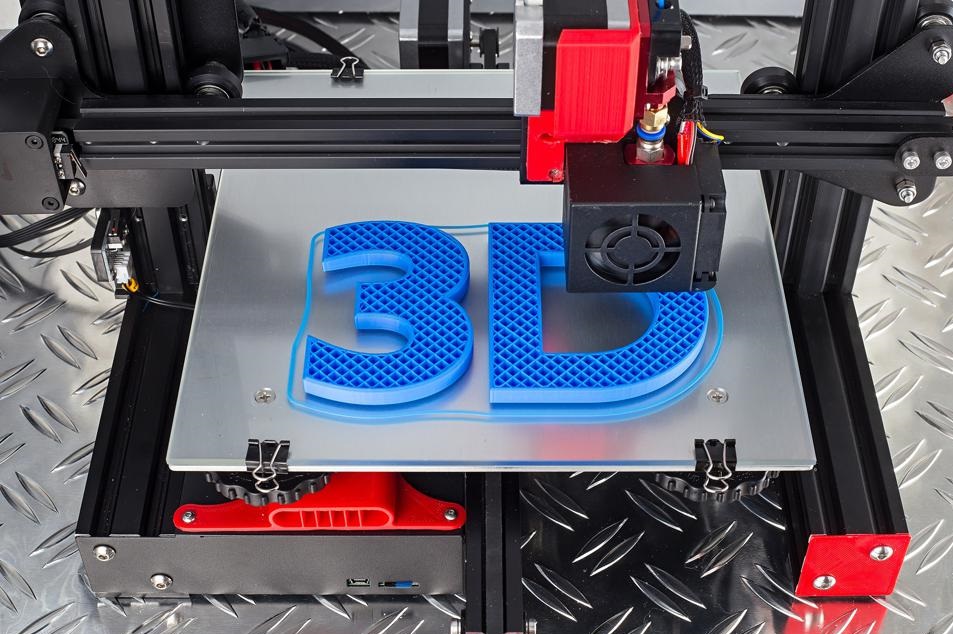

3D printing creates physical parts by successively adding thin layers of material on top of each other. Producing objects using this process offers many advantages over traditional manufacturing techniques. While there are many 3D printing technologies available, the benefits highlighted in this article apply to the entire additive manufacturing industry.

It is not yet clear to what extent 3D printing will complement if not replace current manufacturing methods, but it largely fulfills its role of rapid, accurate, and functional prototyping. Understanding the benefits of 3D printing enables designers to make better decisions when choosing a manufacturing technique for the launch of a final product.

The rapidity

One of the main benefits of 3D printing is the speed at which parts can be produced compared to traditional tools. Simple or very complex models can be printed in just a few hours. The advantage is the rapid verification of the viability of a project while having no creative constraints.

Whereas previously it took days or even weeks to receive a prototype, additive manufacturing brings creators’ imaginations to life in hours.

This disruptive technology allows manufacturers and individuals to considerably reduce their manufacturing times while allowing them to quickly modify any errors.

Manufacture in one-step

One of the biggest concerns for a designer is to manufacture a part as efficiently as possible.

Most traditionally manufactured products require a large number of steps and the order in which they are performed affects the quality and workmanship of the design.

3D printing manufactures in one-step, with no interaction required during the production phase. As soon as the modeling of a CAD file is finalized, it can be transmitted to the printer, which will automatically take care of manufacturing.

This ability to produce a part in one-step dramatically reduces the reliance of companies on complex tooling to complete product realization.

The cost

Defining the reduction of expenses thanks to this new technology is divided into 3 categories: the operating costs of the machine, the cost of raw materials, and the cost of labor.

Machine running costs

Energetically speaking, most desktop 3D printers use the same amount of power as a laptop computer. Professional printers, on the other hand, consume a lot of energy, but have the ability to produce in one-step, which translates into lower energy costs compared to traditional methods.

The cost of materials

The price of additive manufacturing materials varies considerably depending on the technology chosen.

Desktop FDM printers use spools of filament that cost an average of $ 20 per kilogram, while SLA printing requires a resin of around $ 120 per liter. It is difficult to compare the costs of additive manufacturing with those of traditional manufacturing.

To define this more precisely, you need to talk to experts who will analyze your project and define the technology and materials best suited to your needs.

Labor costs

One of the main advantages of 3D printing is the cost of labor. Most 3D printers require only one qualified person to set up the machine and start printing. The 3D printer then follows a fully automated process to produce the part. Compared to traditional manufacturing where skilled personnel are usually required, the labor costs for a 3D printer are almost zero.

To produce at low volume, 3D printing represents a big advantage in time and money.

Risk mitigation

Modifications and rectifications are common in the manufacturing world and can have a significant impact on the final cost of a product design. Being able to verify a design by printing it and making the necessary changes until you get a product ready for use significantly reduces your expense and design time.

Creative freedom

The creative limits that traditional manufacturing places on what gets done are usually not those of additive manufacturing. The complexity of a part is an almost non-existent variable in 3D printing since products are designed layer after layer.

While there are some restrictions on the size of objects that can be printed, most of the limitations of traditional manufacturing are completely eliminated. This allows designers to bring their ideas to life with great creative freedom.

Customization

3D printing not only reduces expenses, mitigates design risks, removes barriers of creative complexity, produces faster in one-step, but also allows you to personalize all your creations. Additive manufacturing is perfectly associated with the design of a unique part. Rather than adapting a whole panel of traditional manufacturing tools to modify its product, 3D printing only requires modifying its 3D model to customize its production. This new technology gives the possibility of producing personalized parts while being profitable.

While some consider the 3D printer to be a gadget with less obvious uses, others, on the other hand, see the 3D printer as a real new industrial revolution. We take stock for you on the possibilities and the limits of this equipment ready to appear in homes around the world.

Make objects of all kinds

The very principle of the consumer 3D printer is to allow individuals to create their own plastic objects. Thus, for example, it is possible to make plastic tableware, which is therefore unbreakable, but also toys for children. The precision offered by the general public 3D printer is sufficient to develop relatively technical objects. The 3D printer is therefore an excellent tool for developing creativity.

Repair your broken items

Very often, when a household appliance breaks, the first instinct is to go to the store or on the internet to buy a model of the same range, spare parts are often not found, even from the manufacturer. With the 3D printer, each user has the possibility of modeling the part that is missing on his computer, then of creating it in relief. The 3D printer is then seen as an anti-consumerist tool to overcome obsolescence.

Create a community

The arrival of the 3D printer on the general public market has given birth to a new community, the “makers”. This community brings together amateurs and designers of objects made through 3D printing. One of the hopes of this community is to participate in the creation of a solidarity movement through the new possibilities offered by the 3D printer, to promote the sharing of digital knowledge.